Downloads

MANUALS

SOFTWARE

FIRMWARE

MANUALS

YourDyno ULTIMATE hardware installation instructions

YourDyno Standard v4/v5 hardware installation instructions

YourDyno Eddy current power supply manual

Stainless Steel Water brake valve manual

(new with zero position sensor)

Water brake valve manual

(previous version)

CANBus plugin manual

SOFTWARE

YourDyno software v3.3.84

(July 5th 2024)

This is the latest YourDyno beta release.

YourDyno software v3.3.71

YourDyno software v3.3.59

This is the latest released YourDyno software.

See how you can do a “live” YourDyno run on with a Pro-Stock engine!

Here is another file you can open to play with the some of the features of the software

To see the software change log and comments go to the following forum post

FIRMWARE

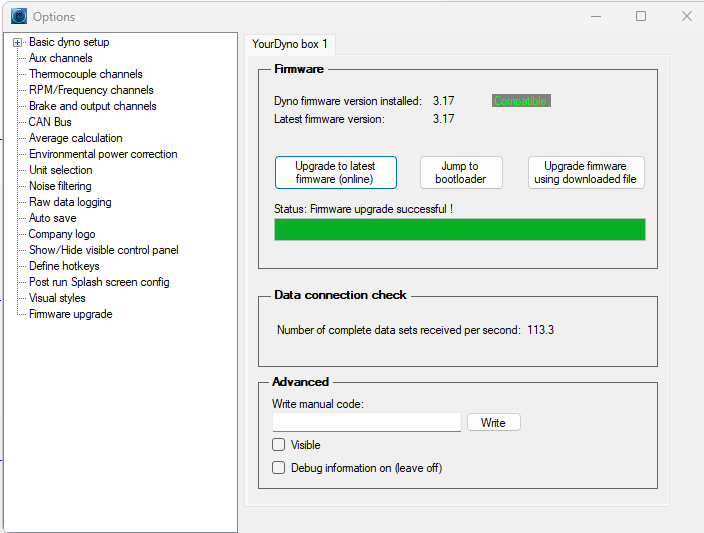

Firmware is automatically updated if you press the “Upgrade to latest firmware” button in Options > Firmware upgrade.

If you upgrade offline then you need to download the firmware file. Use the option “Upgrade firmware using downloaded file”. There is no harm trying the wrong file, you will just get an error message.

For new YourDyno deliveries, all is set up already from the factory, you can just press the button in the software to upgrade the system when new firmware is available.

For YourDyno hardware version 1 you need to enable this by upgrading the bootloader (only once). You can upgrade the bootloader by downloading this file and the downloader program below: YourDyno v1 Firmware bootloader

Please download firmware files below.

Utilities:

Firmware downloader program (only necessary for very early versions of YourDyno, YourDyno version 1).