Automatic brake control

Introduction

YourDyno can control your brake. You can program RPM sweeps or steps or any RPM sequence, plus you can control brake RPM manually all through YourDyno.

Electrically, the brake control is done using an analog 0-5V signal, a PWM (Pulse Width Modulation) signal or a stepper motor DIR/STEP or STEP+/STEP- setup.

This can be used in the following ways:

- Control an Eddy Current power supply

- Drive an RC servo, typically for water brakes or hydraulic brakes

- Drive a servo motor using a motor controller

- Drive a Stepper motor controller

Selecting analog signal or PWM

In order to select the analog output, move the jumpers to the position as shown below (marked AOut1 and AOut2). The other position is used for PWM and stepper motors.

Eddy current brake control

YourDyno can perform Eddy current brake control, for example for a Telma brake. This is pretty straight forward using the YourDyno Eddy current Power supply. It is plug and play with the YourDyno instrument box, and is optimized for speed and control.

CAUTION! When working with Eddy current brake control, be aware that high voltages are generated. Take necessary precautions.

Rewiring the Eddy brake

Eddy current brakes taken from buses or trucks are typically 24V originally, sometimes 12V, but can be rewired to 96V or 192V. You just wire each coil in series. This is described here (scroll down a bit in the file).

How to use an RC servo to control a valve

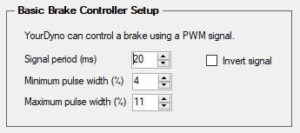

For dynos requiring the control of a valve, for example Water Brake dynos, you can use an RC servo or Servo motor or a stepper motor, see further down. For an RC servo, set up the PWM parameters like this:

With these parameters, YourDyno can directly control the servo.

Selecting an RC Servo

RC servos are not just small, weak servos with max 180 degrees movement. You can find very strong servos and servos with many revolutions from min to max. They can be bought from hobby stores.

Here is a servo capable of 110kg/cm(!) at 180 degrees.

All these servos will require a separate power supply, they cannot be powered directly from YourDyno. Make sure Ground is shared with YourDyno.

Make sure to choose a servo that is fast. The faster the servo, the faster the regulation will work, which means it can deal with sudden changes in power and quickly finds new RPM targets.

Servo motors

Servo motors are motors that run to a certain position based on the input. So they work much like an RC servo, but they can be very powerful. They can be linear or rotational. They are controlled using either a built in or separate servo controller. Ion Motion Control has many types of motor controllers. Check out for example the Roboclaw 30A motor controller.

They can all use a PWM as input, so they are controlled directly by YourDyno.

Servo motors come finished with built in encoders or you can use a standard motor and add your own encoder. You will want a potentiometer type encoder (not a quadrature encoder). They are very simple in operation; if fed by 5V they give out a 0V-5V signal based on the absolute rotational position. Make sure to choose one that has at least as many turns as you need to control your valve. Using a potentomenter encoder you achieve absolute position control, which is what you need. A specific output from YourDyno will translate into an absolute position of your valve.

There are many potentiometer encoders to choose from. Some are hollow shaft and go directly onto your motor shaft. Here is a cheap option with 3600 degree (10 rotations) operating range. It can be connected to for example the Roboclaw controller to turn a DC brushed motor into a servo motor:

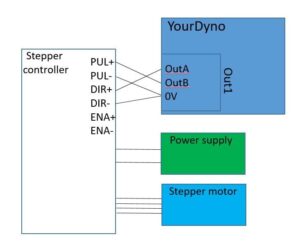

Stepper motor control

YourDyno can also control a stepper motor. You need a stepper motor controller in addition to the stepper motor. There are many to choose from. You choose mostly based on the current you need. Here is how to connect the stepper controller.

The PID controller

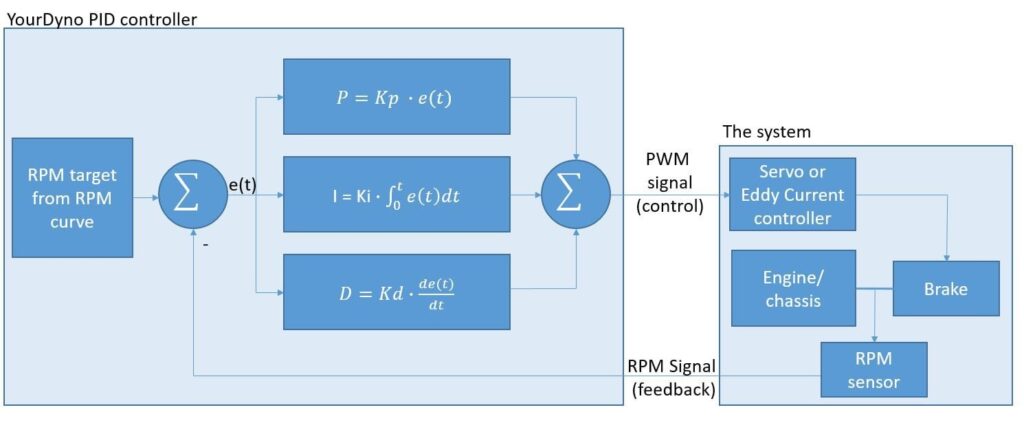

Control of the brake signal is implemented in the software using a so-called PID control loop. Using this, you need to setup 3 parameters for your brake, Kp, Ki and Kd.

Here is a schematic of the PID controller with its outputs and inputs:

e(t) is the Error signal (actual RPM – target RPM) which should be as small as possible. The 3 equations P, I and D use this error signal to create 3 components that are summed together to create the PWM signal, which controls the brake. The actual RPM is fed back again to create e(t) together with the target RPM (which by now might have changed slightly depending on the curve).

The quick start guide for a roller based eddy brake is to set Kp = 0.5, Ki = 0.5 and Kd = 0.05.

If you see oscillations, a way to see what’s going on is to plot the Kp, Ki and Kd vs Time. You will then see which parameter is oscillating. Very often it is Kp that needs to be reduced.

It is also useful to look at Brake %, RPM and Target RPM in the same graph. Here you can see what the brake is doing vs what it should be doing.

You don’t need to understand how the PID controller works, but you should however have a certain feel for what the three parameters, Kp, Ki and Kd do if you want to optimize your system. Read on!

Brake % = Kp + Ki + Kd

Kp:

This is the proportional component

Higher Kp = less error, so you want Kp as high as possible

Too high Kp = oscillations, an unstable system

Ki:

This is the integral component. This component is a steady state error remover.

Higher Ki = shorter time to reach 0 steady state error

Too high Kp = oscillations, an unstable system

Note that with any positive Ki, the steady state error will eventually become 0. The parameter only sets how fast it becomes 0.

Kd:

This is the derivative component. It dampens and slows down the response. It can in many setups help increase stability, but make sure to use small numbers, like 0.03-0.05.

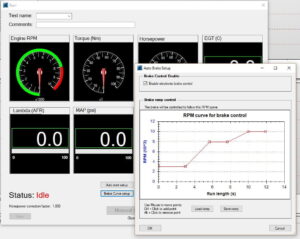

The brake curve

The brake curve sets RPM that the system will follow during a run.

Any curve is supported, be it steady state at a single RPM, continuous ramp, or whatever.

Manual brake control is also supported.

A word of caution

When YourDyno box is connected to the PC, there is a short period of time before it boots up when the brake output is undefined. If YourDyno software is not running when you plug the box in, the output continues to be undefined until the software is started. Your system must support this. In many cases this means start up the YourDyno software and connect the YourDyno box before turning power on to your brake controller.